Julin Intelligent Mattress Automation Equipment - The

working principle of the intelligent machine gripper: when it needs to be stored, the mattress is conveyed by the roller and automatically sensed and automatically lifted; when the mattress needs to be output, the lifting mechanism automatically lowers the mattress to the roller line;

Suitable mattress size: L length 1800-2200 mm, W width 500-2200 mm, H height 15-300 mm;

Features:

①.Visual positioning, fully automatic up and down transportation of mattresses;

②. Adaptively produce mattresses of different specifications and sizes;

③. Self-adaptive spring mattress, sponge mattress, etc., automatic deviation correction compound.

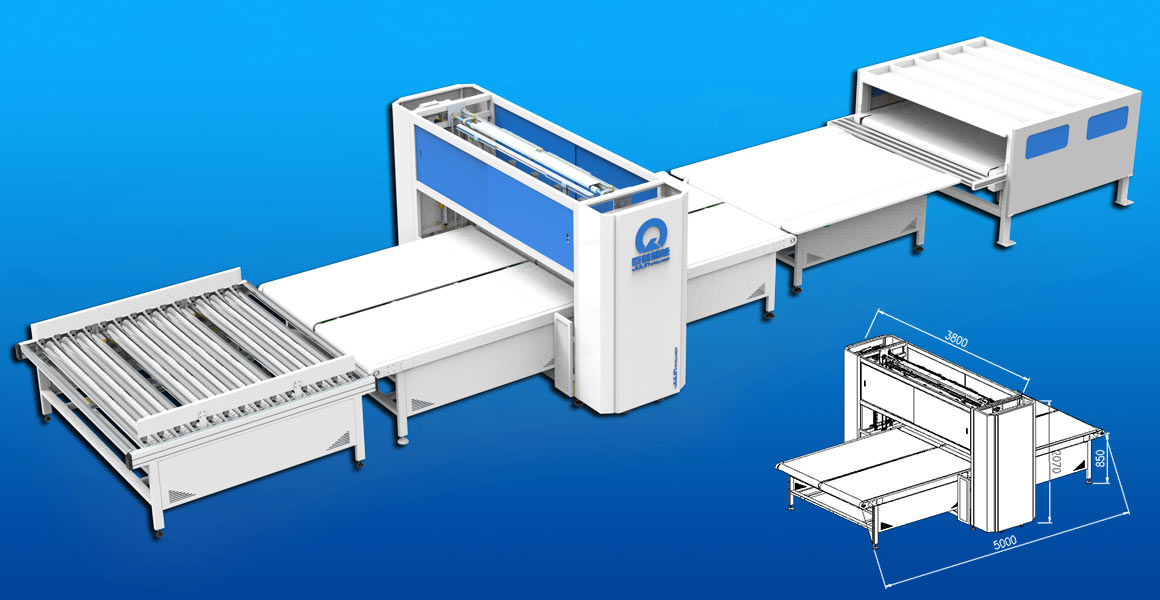

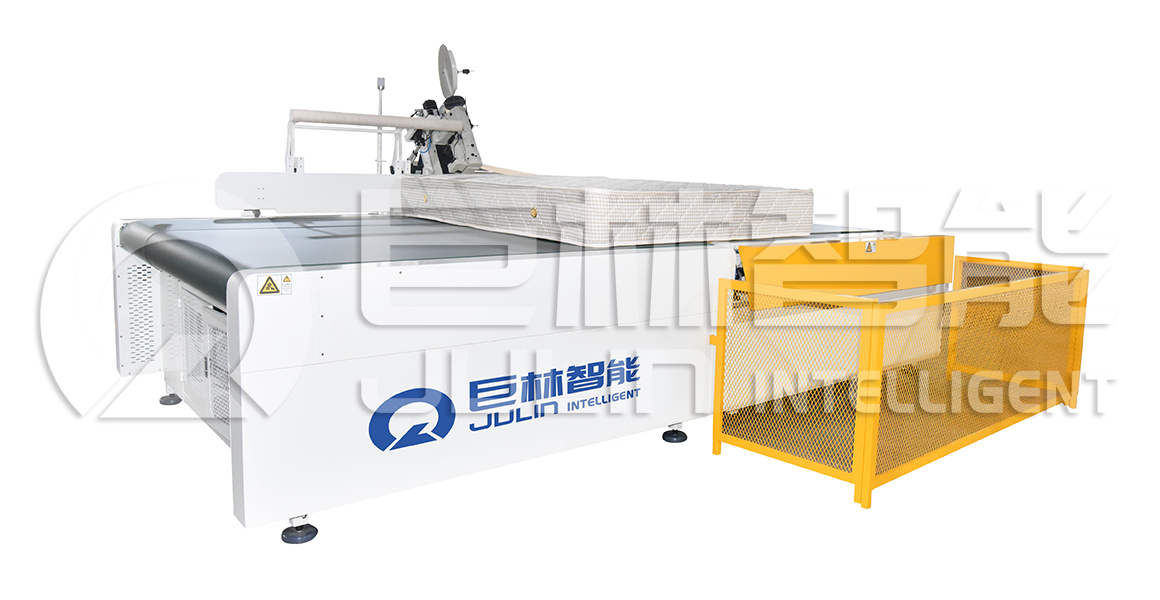

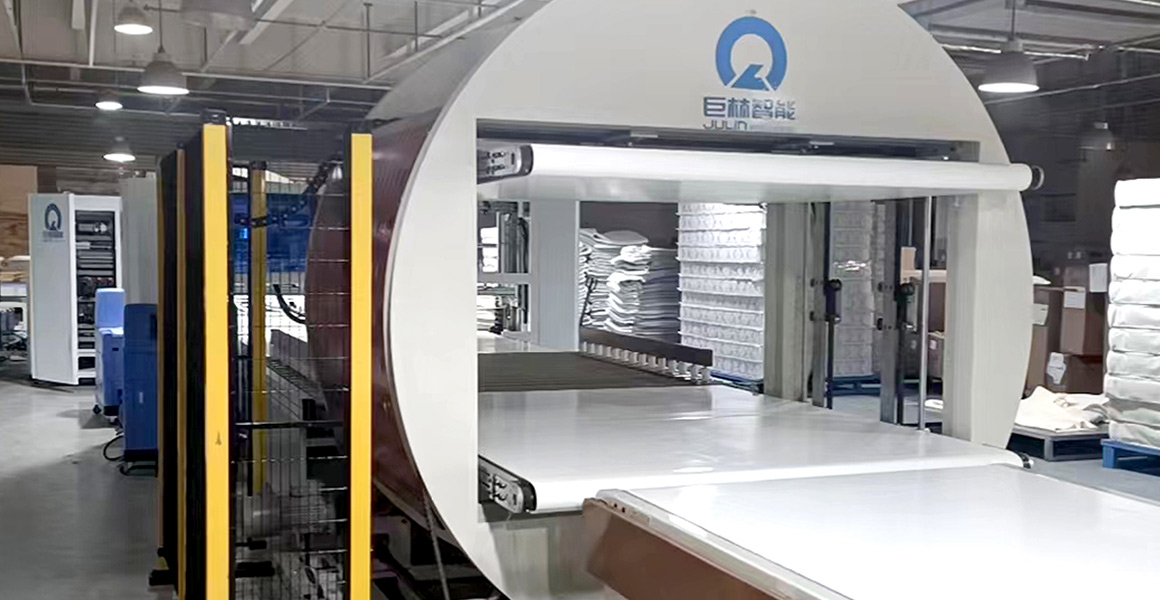

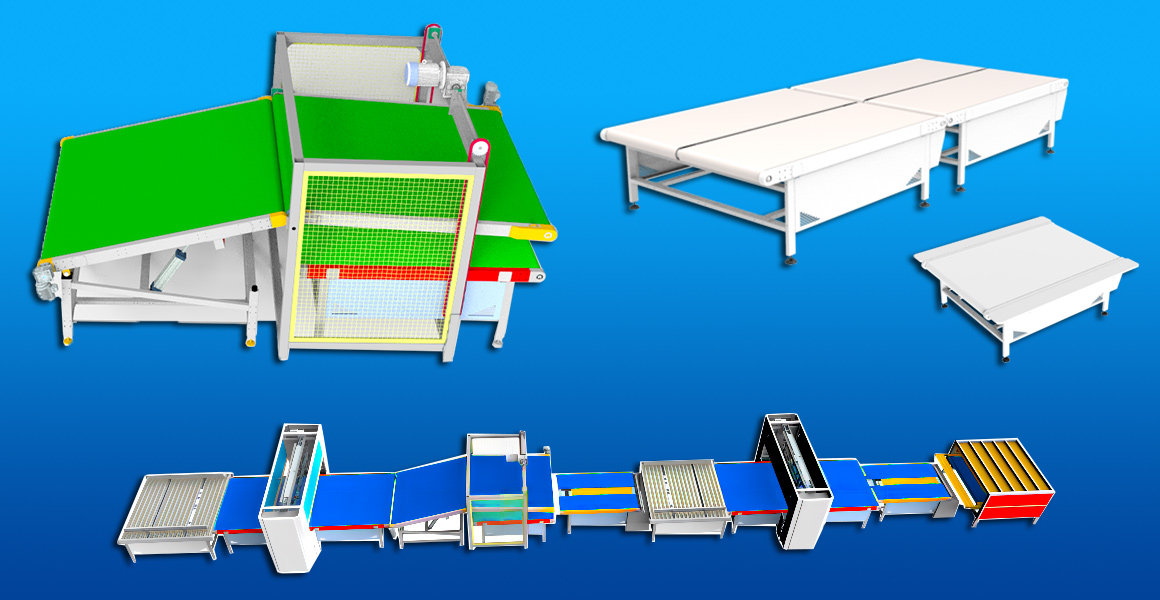

Julin intelligent mattress automation complete set of equipment 1. Fully automatic intelligent mattress hot melt glue spraying machine

1. Product structure: high-quality rectangular steel pipe as the skeleton, &3.0 cold-rolled plate as the protective frame, and &2 imported silicon rubber belt as the transmission medium;

2. Belt material: high-quality silicone belt, with good anti-sticking durability (thickness ≤ 2 mm imported brand);

3. Dimensions: Customized design according to customer needs, and the height can be determined after more requirements;

4. Conveying speed: 0~46 m/min (using servo motor drive control, adjustable speed);

5. Product features: Silicone belts are clean and sticky, and thin materials can be positioned precisely; if hot melt glue accidentally drips on the belt, it is easy to clean.

Technical parameters of automatic intelligent mattress hot melt adhesive spray production line equipment:

1. Plane conveyor belt material: high-quality silicone belt, with good anti-sticking and durability (thickness ≤ 2mm imported brand);

2. Hot melt machine capacity: 58KG or above;

3. Surface height of automatic glue spraying production line: 850mm ± 50mm;

4. Conveying speed: 46m/min;

5. Automatic spraying, automatic positioning function (accuracy ± 3mm);

6. The amount of glue can be adjusted automatically;

7. A variety of spray patterns are available, such as strip, S-shaped, back-shaped, etc.;

8. The lowest position of the spray gun is 850mm, the highest position is 1300mm, and the stroke is 450mm;

9. Ultrasonic probe;

10. Control up and down reciprocating lifting;

11. 8 sets of glue guns prepared by Julin glue machine (6 inside + 2 around) + independent nozzles), 5 nozzles in a single line;

12. The touch screen controls the use status of the switch gun head (according to the product setting switch cycle rules (example 8+6+6+8) to save the product number);

13. Each glue gun is equipped with an independent servo, which can be automatically programmed to shift.

Julin automatic glue spraying machine effectively reduces the cost of raw materials and labor. Precisely controlling the amount of glue sprayed can fully save glue; the degree of automation is high, and it can follow straight lines and curved glue spraying tracks to improve production efficiency; the product quality is high, and the possible damage caused by labor is reduced. Error; the high degree of intelligence has greatly enhanced the popularity of the mattress brand.

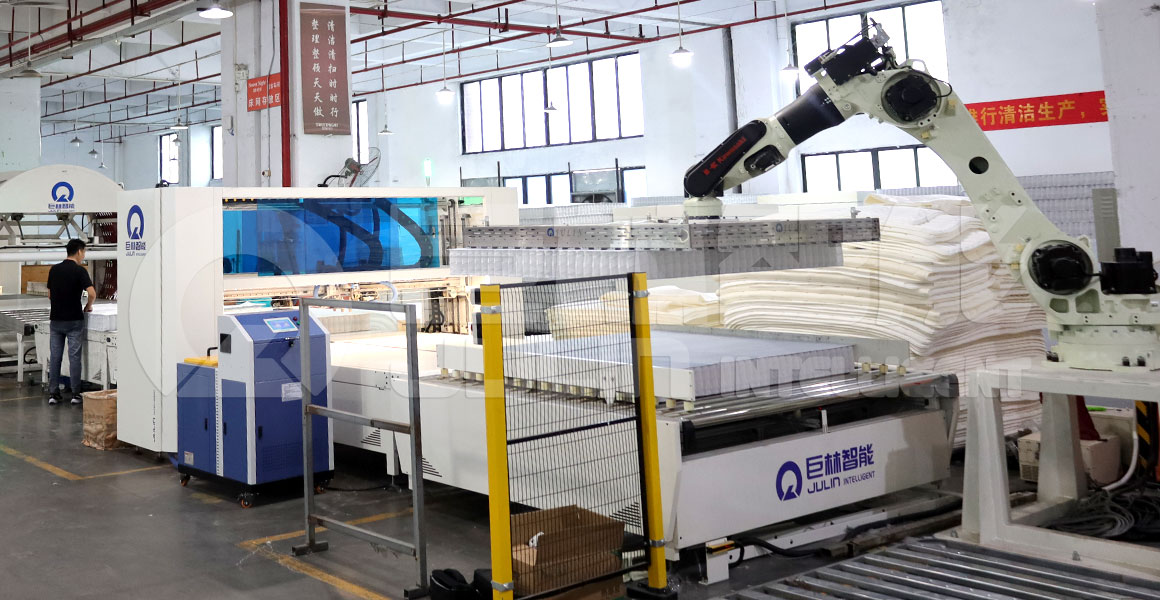

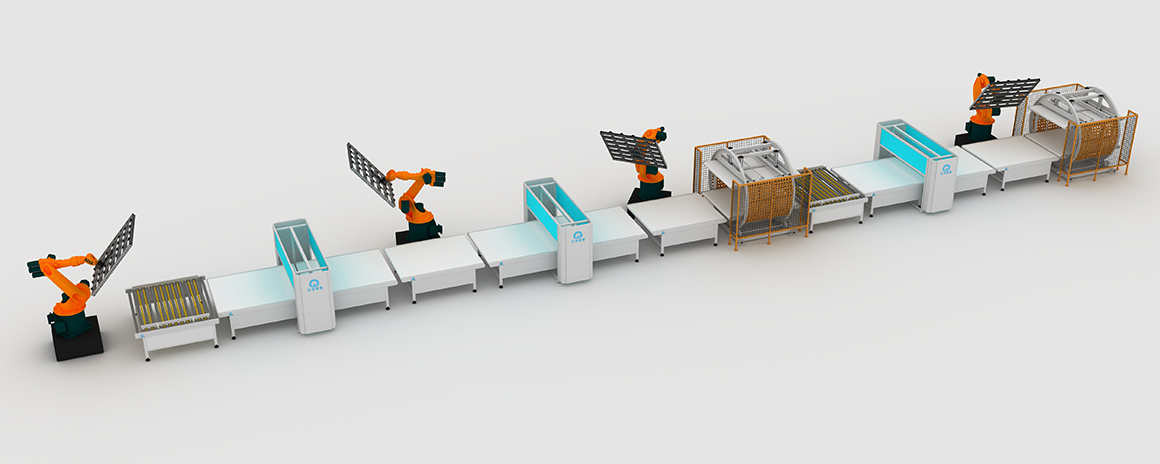

2. Special robot for intelligent mattress grabbing

Mattress-specific AI vision Julin intelligent robot can grab and make the bed net to grab and transmit the mattress. Julin intelligent robot adopts the world's leading industrial robot KUKA robot imported from Germany, which is widely used in BMW, Mercedes-Benz and other well-known enterprises. Mature and advanced, small size, less space occupation, high degree of automation. Julin Intelligent can select the appropriate robot mattress equipment according to the needs and budget of customers!

1. Adopt computing intelligent control system to introduce RFID chip technology, MES management system and fully automated production equipment, introduce robot mattress composite system, robot detection, unmanned and intelligent;

2. High degree of automation, equipped with automatic bed spring machine, automatic steel edging machine, automatic bottoming machine, automatic glue spraying machine, robot mattress precision compounding, automatic compression packaging machine, automatic palletizing machine, semi-automatic edging machine and AGV Automatic running trolley, three-dimensional transportation system, developing towards unmanned production.

Julin Intelligent Mattress Robot Deviation Correction Composite Gripper has the function of automatic deviation correction after grabbing mattress fabrics, sponges, latex and other filling layer materials, bed core liners, fully automatic PLC control, and the equipment production capacity can reach 3000 sheets/day.

Automatic loading: the bottom/top layer of sponge mattress is moved from the tray to the designated position, and the system automatically completes the cotton separation and loading;

Visual positioning: incoming materials are automatically positioned by AI vision without manual intervention;

Adaptability: the system can adaptively produce mattress products of different sizes;

Flexible clamping: to avoid the edge of the mattress from opening, adopt a flexible clamping mechanism to complete the top cotton compounding process;

Combination correction: within the allowable cutting error range, the system automatically corrects the composite error through AI visual calculation.

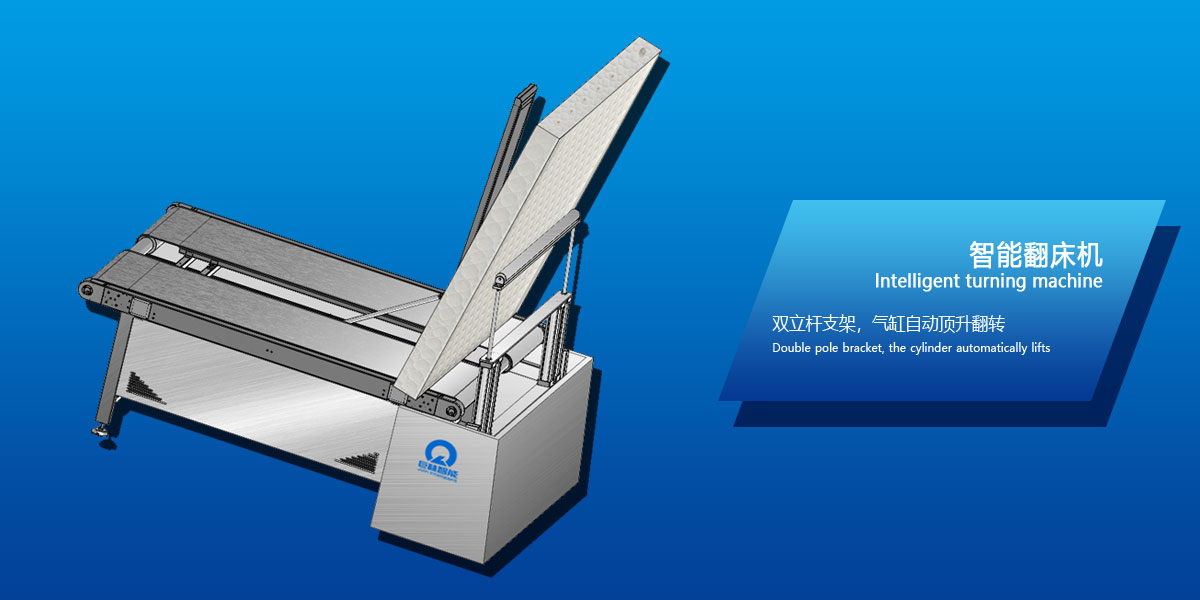

3. Intelligent mattress turning machine  The cylinder jacking bracket is used to turn over, the pole support is turned over, and the cylinder is automatically lifted to connect the plate after turning over, which is suitable for turning and lifting of various hard and soft mattresses such as spring mattresses and sofas. The bed turning machine has a large load-bearing capacity, reducing manual heavy physical operations.

Features of Julin Intelligent Mattress Turning Machine Equipment: ①. It can ensure the cleanliness of the mattress and prevent contamination caused by manual touch. It can turn over the mattress within 100KG;

②. The performance of the servo motor is stable and the efficiency is higher;

③. The combination of double pole cylinder jacking bed turning machine can effectively improve the accuracy of mattress turning.

Julin smart mattress special double-layer edging machine is mainly used for the edge between the upper and lower fabrics and side fabrics of spring mattresses, and is also suitable for sewing other upholstered mattresses, sleeping bags, and tents.

This machine has the characteristics of head elevation adjustment, head lift adjustment, sewing speed adjustment and so on. During sewing, the mattress is moved by the conveyor belt of the workbench for sewing, using PLC program control and artificial intelligence operation, the mattress can automatically walk, automatically turn corners, and automatically turn over during sewing, which improves the sewing speed. The machine head can automatically lift, decelerate and recover automatically at the corners of the mattress, which improves the sewing quality and solves the problem of inward warping of the four corners. The sewing of the mattress only needs to be operated by one person, which improves the work efficiency and reduces the labor intensity. It is an ideal equipment for the production of medium and high-end mattresses and production lines.

It has the following characteristics:

1. Imported or domestic machine heads can be used according to customer requirements.

2. The table can be lifted and lowered manually, and the inclination angle of the machine head can be adjusted manually.

3. Manual speed adjustment for sewing and carriage travel, and manual deceleration for turning positions.

4. The sutures are straight, even and beautiful.

5. Smooth operation, low vibration and low noise.

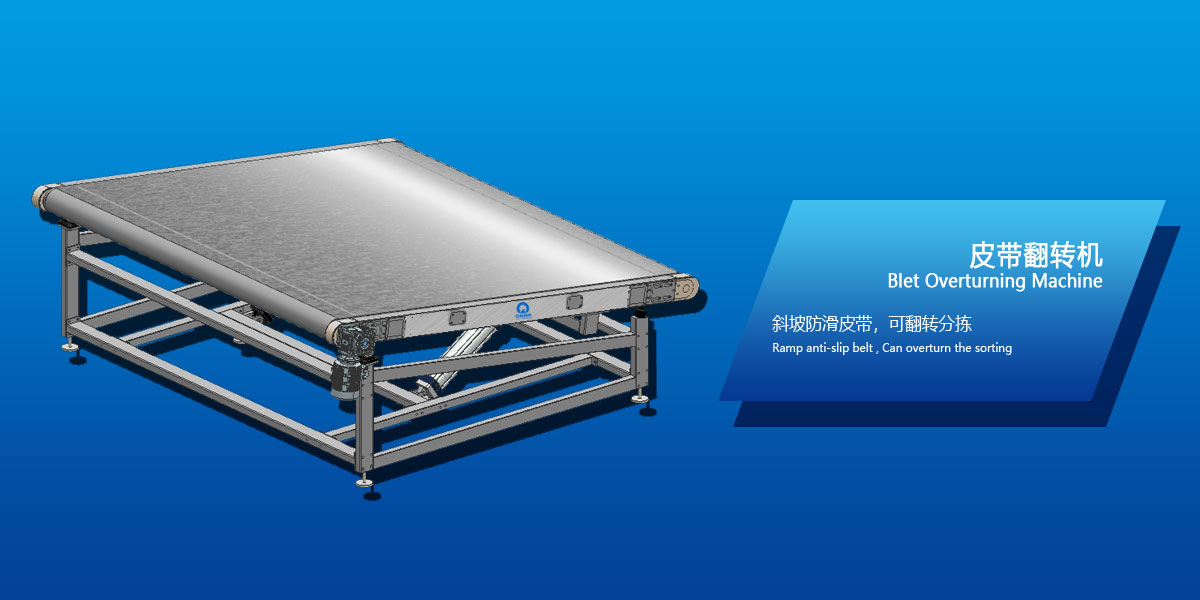

5. Intelligent mattress belt turning machine

Julin intelligent mattress professional equipment upper and lower belt turning machine can flexibly adjust the up and down direction of mattresses according to production needs, improve sorting efficiency, can adapt to the turning requirements of soft beds of different specifications, and provide safe, stable and effective process transportation.

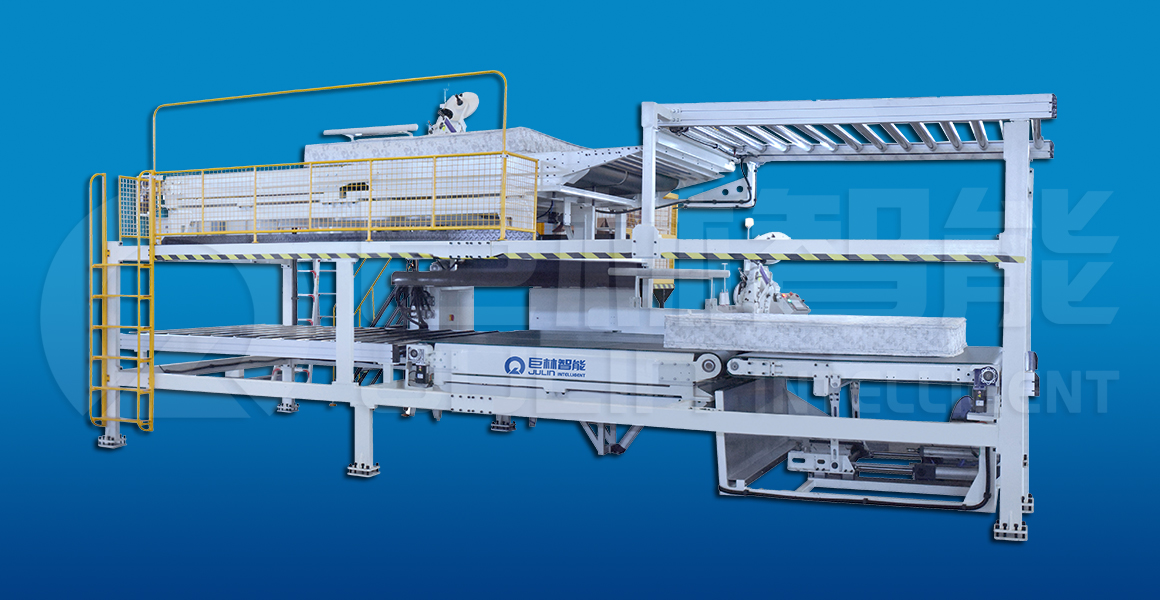

6. Smart mattress automatic stacker

Stacker technical parameters:

1. Product structure:

①. High-quality 50x100, 40x80 thickened rectangular steel pipe is used as the main frame, and cold-rolled plate is used as the protective frame;

②. The special K821 thickened aluminum profile is used as the protective frame, and the super-large diameter 76 mm stainless steel accumulation roller is used as the transmission medium.

2. Dimensions: L 4280 x W 3560 x H 3260 mm

3. Working beat: ≤ 30 seconds/sheet

4. Stacking height: 2200 mm (whole chop)

5. Working principle:

The mattress is fed into the equipment by the roller line, and is precisely positioned by the photoelectric. The motor pulls the entire tooling to stack and position up and down, and the timing belt and the roller line are relatively reversed to realize the whole mattress stacking.

6. Product features:

①.Ring type power transmission structure, stable power transmission, smooth lifting movement up and down, and synchronous actions;

②. Guided by linear guide rails, the movement is stable and the service life is long;

③. There is a pallet limit on the bottom, and a rear limit on the tooling, which makes the stack more neat and easy to operate and place;

④.PLC intelligent control, which can realize multiple intelligent distribution of multiple sets, and has a full chop alarm prompt.

There are some common problems in the traditional palletizing and packaging workshops, such as: densely populated, unable to recruit people during peak hours, and shortage of personnel; the quality of palletizing and packaging cannot be guaranteed, and there are misoperations such as sending wrong goods, missing assembly parts and gifts. .

The stacking advantages of Julin intelligent finished mattresses: high degree of automation, reduced stacking labor intensity, and reduced floor space.

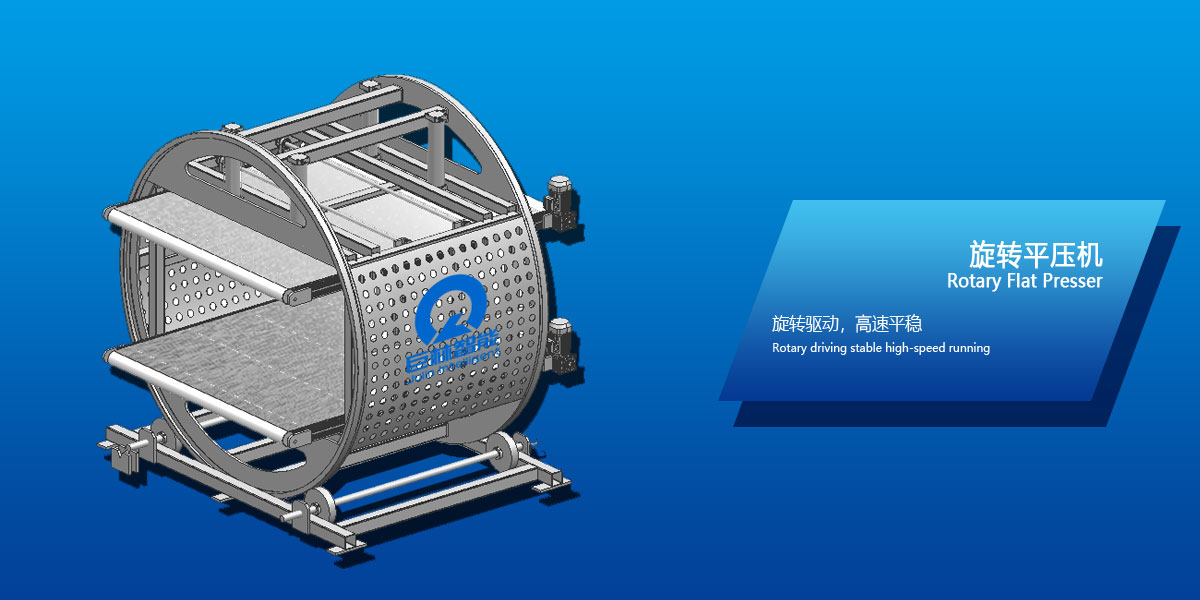

7. Intelligent mattress rotary press

Julin Intelligent Mattress Flip Press Technical Parameters:

1. Product structure:

①. High-quality 60x100, 80x80 thickened rectangular steel pipe is used as the skeleton, cold-rolled plate is used as the protective frame, and the gear and rack are meshed with relative movement and pressed. With the power of the large-load motor, the press can rotate steadily;

②. The belt adopts &2 imported silicon rubber belt transmission medium, and the belt is equipped with guide strips to prevent the conveyor belt from running sideways.

2. Dimensions: L 2500 x W 2700 x H 2720 mm;

3. Running speed: 23 m/min;

4. Working principle: The mattress enters the press machine for precise positioning by universal photoelectricity, with the cylinder as the power, the rack and pinion as the medium, and the optical axis as the guide, so that the upper and lower belt lines perform a pressing action, and then use the docking photoelectric sensor to pass through the PLC. Intelligent control of the pressing height. Utilize pressing and waiting for the neutral position, the entire press is driven by a large load motor to realize 180° rotation, and the conveyor belt is reset after it is in place, and the mattress output device enters the next process.

5. Product features: ①. Mattress flipping and flattening integrated design, reducing equipment, saving space and time;

②. The white silicone belt is used as the medium, which is neat and clean and easy to clean;

③. The cylinder is used as the power, and the gear and rack are used as the relative movement, and the belt is pressed smoothly;

④.Thickened plastic plate is supported by the belt, with low resistance and silent transmission;

⑤. The high-power motor drives the rotation, the rotation is stable and the precision is high.

(Julin modular design, fast installation, stable quality, convenient maintenance and repair, low maintenance cost)

Julin intelligent mattress flipping and flattening machine consists of flipping main body, feeding device, stacking clamping mechanism, control pipeline, hydraulic system, electrical console, operating system, safety fence, etc., and can adapt to different specifications of soft beds. Flip and flatten the requirements, provide safe, stable and effective process transportation, and realize the operation goal of converting the front side into the back side or converting the back side into the front side.

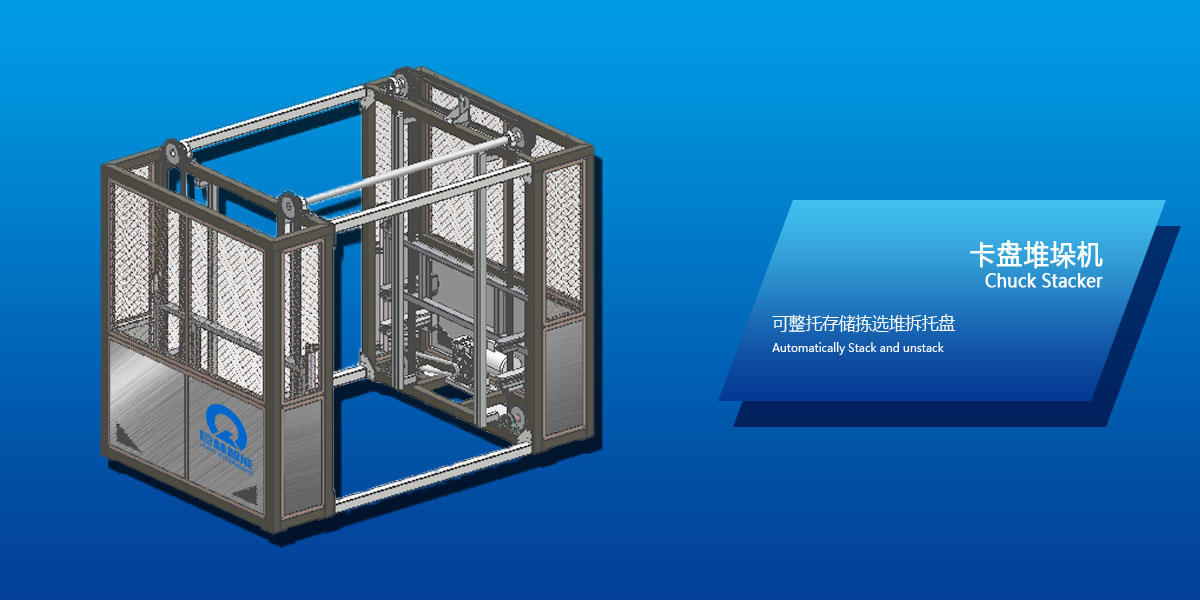

8. Intelligent mattress chuck stacker

The pallet stacker is mainly composed of upper beams, columns, lower beams, loading platforms, forks, control systems, communication systems and other parts. It is the core equipment of automated three-dimensional warehouses. Automatic access and handling, material storage unit is pallet.

9. Smart Mattress Automatic Dust Collector

Julin intelligent special mattress blowing dust, dust removal and sterilization cleaning machine can effectively improve the factory quality of mattresses.

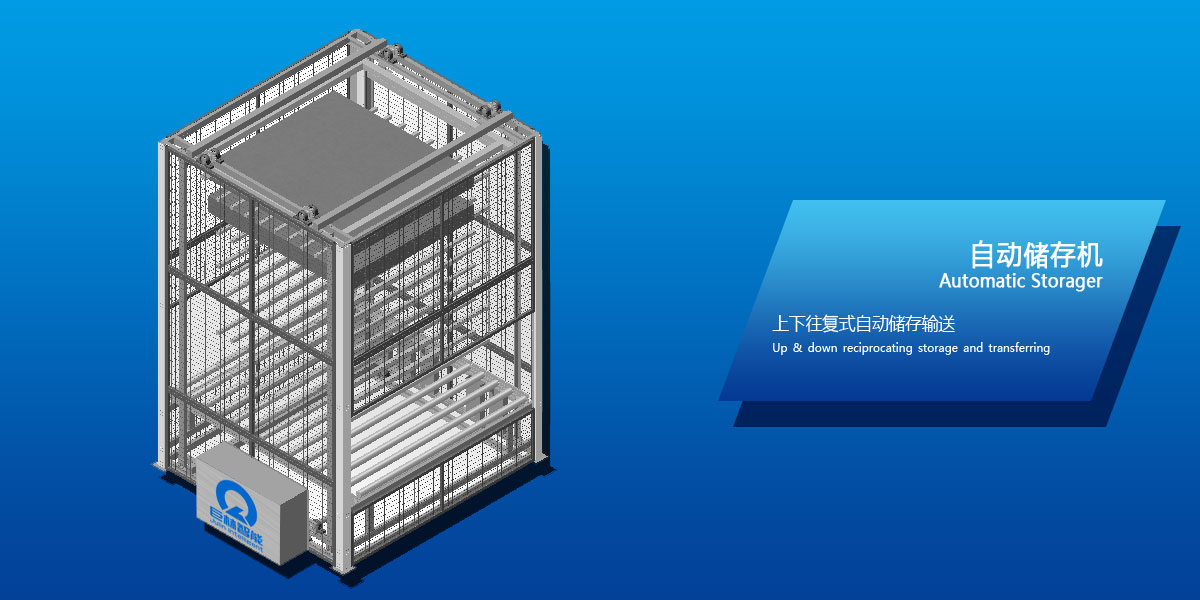

10. Intelligent mattress automatic storage machine

Julin Intelligent Mattress Automatic Storage Machine is mainly used to store mattresses in production, and can be customized for up and down reciprocating automatic storage and transportation.

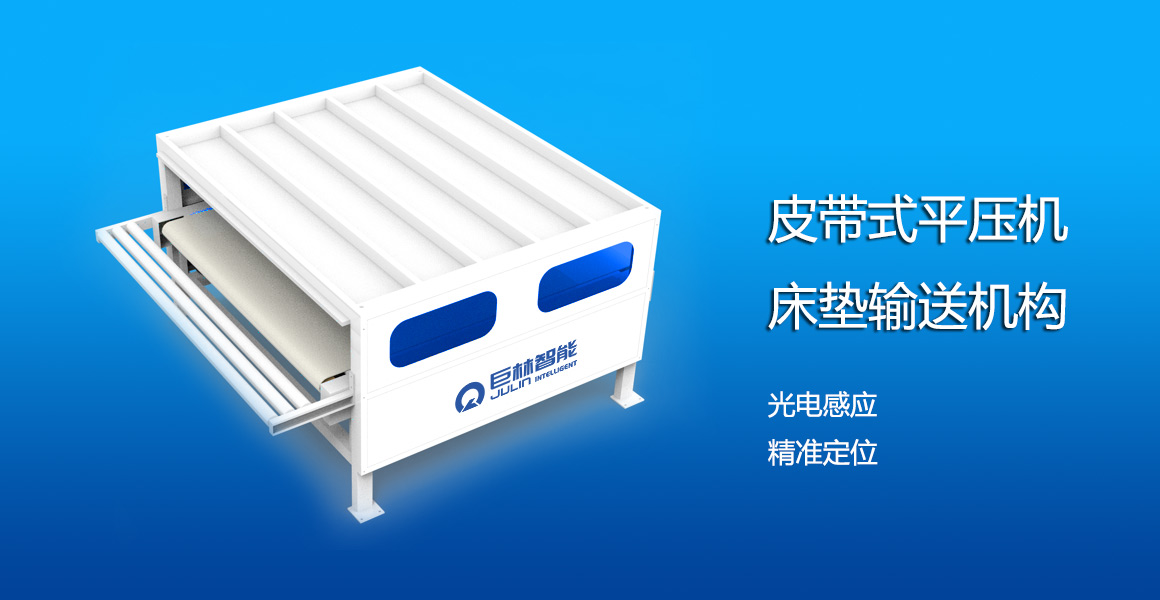

11. Intelligent mattress flat press

Julin Intelligent Mattress Flat Press Technical Parameters:

1. Type: belt conveyor mechanism;

2. Dimensions: L 2250 x W 2500 x H 1360 mm (line height 850 mm);

3. Applicable specifications: mattress height is 100 mm~400 mm;

4. Conveying configuration: &2 Imported silicone belt, white, with guide strips on both sides of the belt;

5. Operating speed: 26 m/min. 0.4Kw geared motor;

6. Working principle: The mattress enters the press machine with universal photoelectric precise positioning, and the airbag is pushed from top to top, and the mattress positioning of different heights is positioned by photoelectric positioning to ensure sufficient extrusion mattress. Nonconforming products appear.

12. Julin intelligent mattress automation and other related equipment

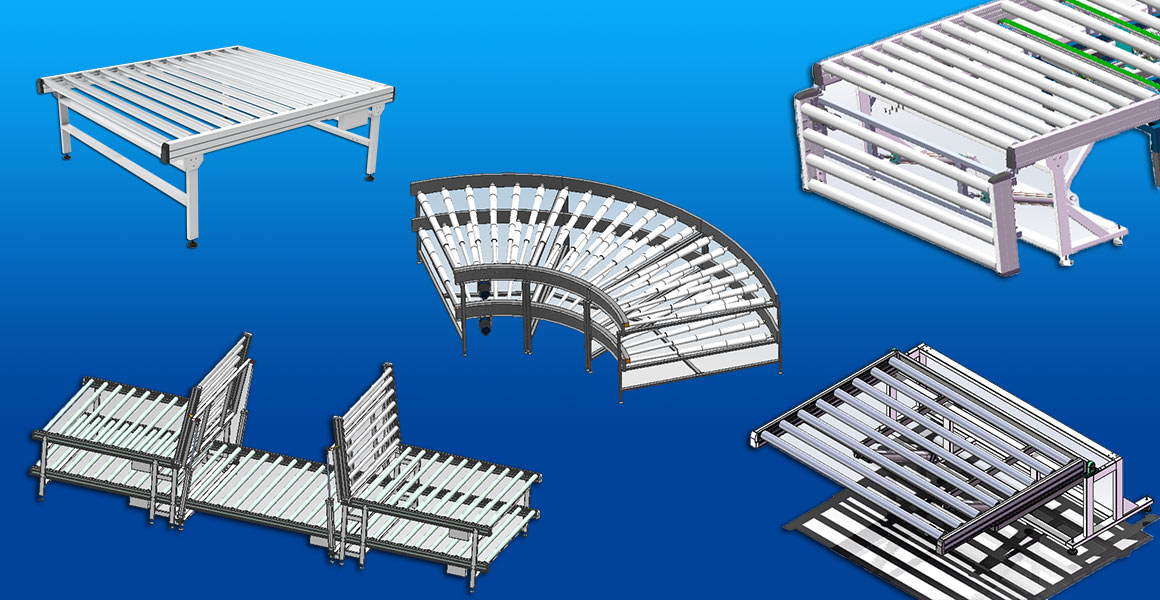

Julin Intelligent Mattress Automation Equipment Technical Parameters:

【Roller 】

1. Product structure: use high-quality 40 x 80 thickened rectangular steel pipe as the skeleton and special K821 thickened aluminum profile as the protective frame, and use a super-large diameter 76 mm stainless steel accumulation roller as the transmission medium;

2. Line width: L2500 x W2200 x H750 mm (the line height can be adjusted from 750 mm to 820 mm);

3. Roller pitch: no more than 150 mm;

4. Running speed: 23 m/min (can be customized according to customer requirements);

5. Load: dynamic load 250 kg, static load 500 kg;

6. Control: Mitsubishi PLC control, one-button start, imported photoelectric positioning, 10-inch touch screen operation, high-definition dynamic display, accurate positioning and fast response;

7. Product features:

①. Segmented independent electrical control, which can be customized according to the actual needs of the factory;

②. The line segment is equipped with a special anti-scratch buckle developed by our company;

③. Stainless steel accumulative roller conveying, which can ensure the cleanliness of materials, anti-deviation conveying, anti-overload protection, silent conveying, and easy cleaning.

Julin Intelligent can customize non-standard single-layer, double-layer, multi-layer roller lines, mattress machinery automation equipment turning machines, modular design, fast installation speed, stable quality, convenient maintenance and repair, and low maintenance costs.

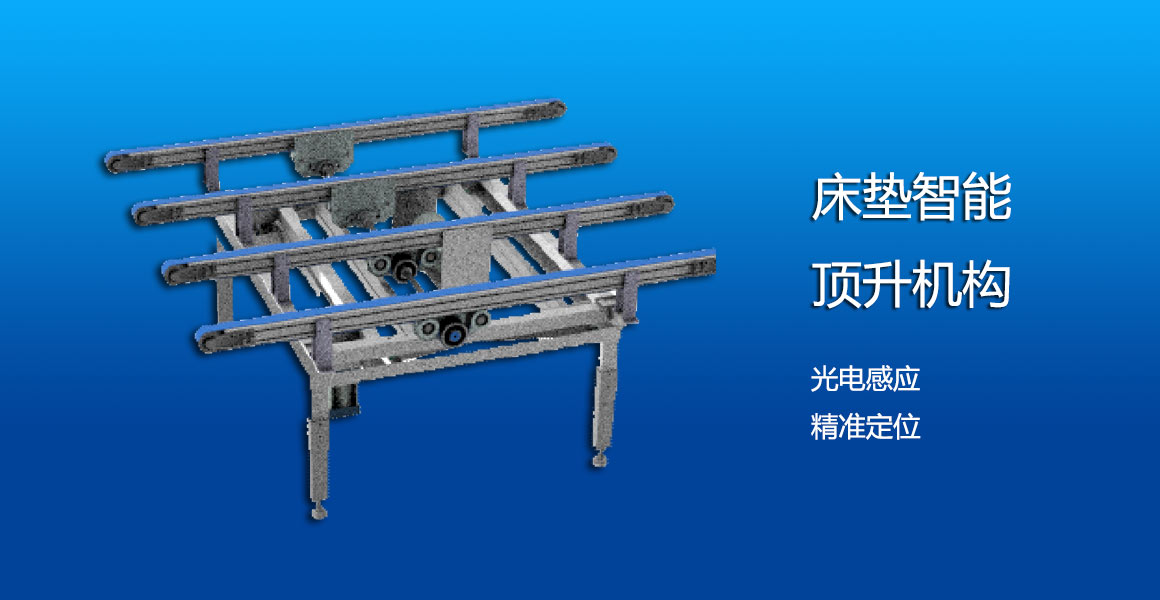

Julin Intelligent Mattress Automation Equipment Technical Parameters:

[ Mattress Lifter ]

1. Product structure: The whole line adopts high-quality thickened rectangular steel pipe as the skeleton, GY special aluminum profile, & 2.3mm blue synchronous belt as the transmission medium, double cylinder jacking, and the driving structure adopts advanced pneumatic scissor fork structure;

2. Dimensions: L1850 x W1500 x H720 mm (the height of the whole machine can be adjusted from 720mm to 800mm, and the lifting stroke of the cylinder is 80mm);

3. Conveying: the blue synchronous belt is used as the transmission medium, the drive is stable and the service life is long;

4. Operating speed: 23 m/min;

5. Load: dynamic 250 KG, static 500 KG

6. Features: fast speed, high efficiency, heavy weighing, high power transmission, stable performance,

7. Working principle: The photoelectric precision senses the workpiece in place, the cylinder automatically jacks up, and then the motor drives the synchronous belt through the sprocket drive. The conveying direction of the synchronous belt is 90 degrees to the conveying direction , so as to achieve the purpose of translation and steering of the workpiece.

Julin intelligent modular design, fast installation, stable quality, convenient maintenance and low maintenance cost.

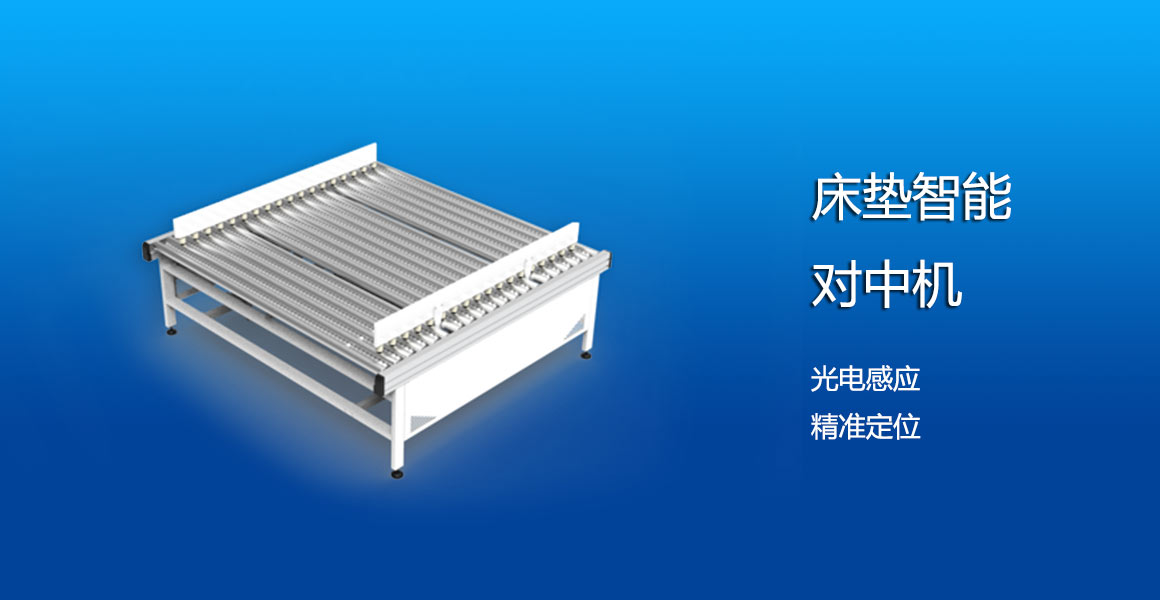

Julin intelligent mattress automation equipment technical parameters:

[mattress centering machine ]

1. Product structure: high-quality 40x80 thickened rectangular steel pipe as the skeleton, special K821 thickened aluminum profile as the protective frame, and a super-large diameter 76mm stainless steel accumulation roller as the transmission medium;

2. Dimensions: L 2500 x W 2200 x H 750 mm (line body height 750mm~820mm adjustable);

3. Running speed: 20-30 m/min;

4. Working principle: The conveying line is driven by a geared motor to reach the position, and an automatic clamping and centering device is installed under the line body. After reaching the position, the cylinder can be automatically jacked up, the auxiliary wheel is used for sliding, and the servo motor is used for absolute value movement to drive the rack and pinion. Drive the guide plates on both sides to automatically complete the clamping work;

5. Product features:

①.Stainless steel accumulative roller transmission, which can ensure the cleanliness of materials, anti-fabric wrapping, light sound and convenient cleaning;

②. The positioning of the servo motor is centered, the performance is stable and the efficiency is higher;

③. The combination of iron plate + guide wheel is suitable for diversification of product types.

Julin Intelligent can customize various mattress non-standard centering mechanisms, mattress automatic centering equipment, modular design, fast installation speed, stable quality, convenient maintenance and repair in the later period, and low maintenance cost.

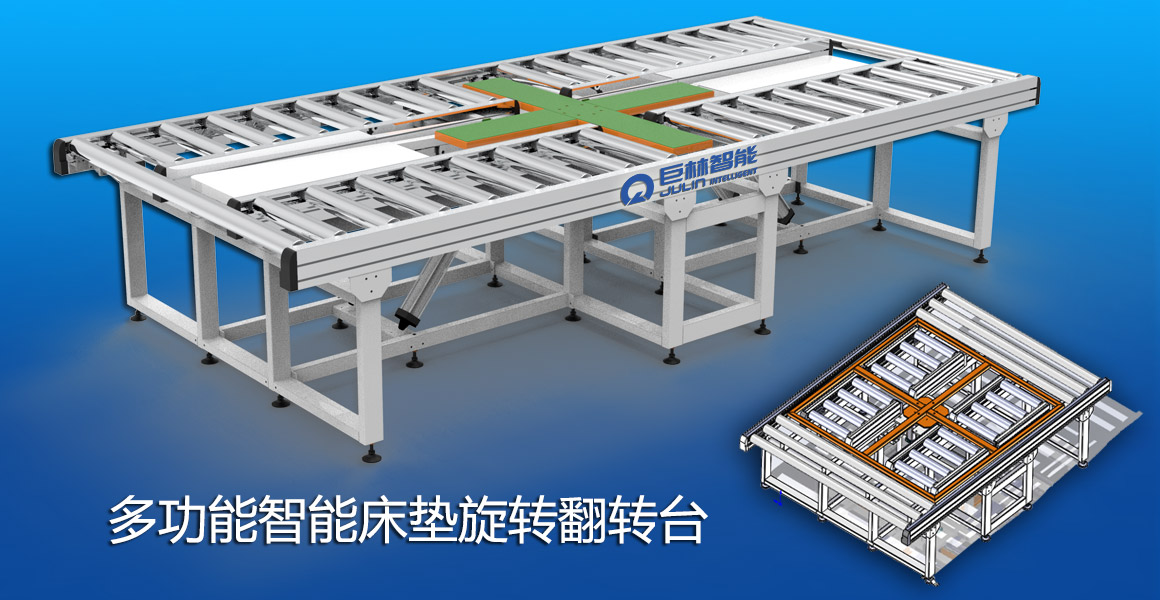

Julin Intelligent Mattress Automation Equipment - 【Rotary Flip Table 】

Julin Intelligent can customize various non-standard mattress equipment. The mattress automatic rotation and turning table is used together with the roller line to save manpower. Intelligent dust-free automatic turning improves production efficiency and product quality.

1. Product structure: use high-quality 40 x 80 mm thickened rectangular steel pipe as the skeleton, & 3.0 cold-rolled plate as the protective frame;

2. Dimensions: L 2400 x W 2166 x H 750 mm (height of the machine can be adjusted from 750 mm to 820 mm);

3. Conveying: Adopt & 2.0 wear-resistant and anti-static high-quality belt, the belt is supported by 20 mm plastic plate, and guide strips are equipped on both sides of the belt;

4. Speed: 23-50 m/min (set according to the location of the plan);

5. Load: dynamic 250 KG, static 500 KG

6. Features:

①. Imported photoelectric induction ultra-sensitive and precise intelligent start;

②, high-definition full-color touch control large-screen dynamic display;

③. Thickened 20mm plastic laminated board is used as belt support, low resistance and silent transmission;

④. Segmented belt conveying, precise positioning, anti-scratch hands, wide application range (thin and thick materials can be accurately positioned and controlled);

⑤. The drive can be driven by a servo motor or a worm gear reducer.

Julin intelligent mattress belt can form a production line with other mattress special equipment, and can customize a suitable automatic assembly line according to the actual site of the customer's mattress factory, and can form a multi-layer mixed combination production line!  High-quality silicone belt, good anti-sticking and durable (thickness ≤ 2 mm imported brand), side foldable flap, the flap width is 250 mm, the width can be freely selected according to the size of the mattress, and the operation is simple and convenient.  Julin modular design, fast installation, stable quality, convenient maintenance and low maintenance cost.

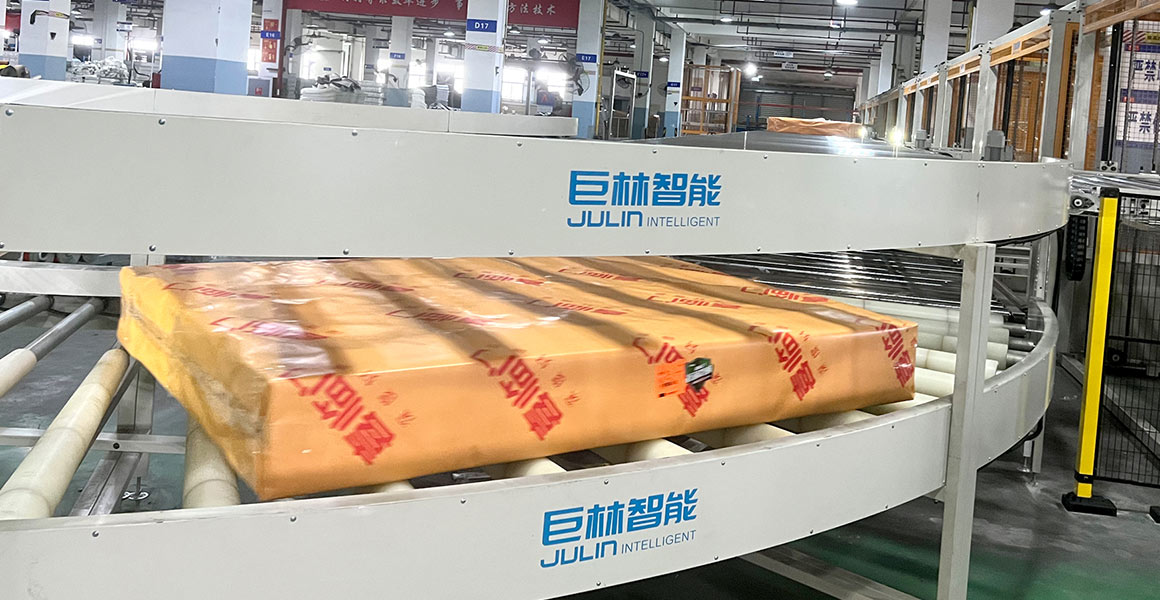

Julin Intelligent Mattress Automation Equipment Belt Conveyor Line Case

Julin intelligent mattress automation equipment customer case

Julin intelligent mattress automatic production line equipment

|