|

MES (Maunfacturing Execution System), AMR (Advanced Manufacturing Research), an American advanced manufacturing research institution, defines MES as "a workshop-oriented management information system located between the upper planning management system and the underlying industrial control". /Management provides execution of plans, tracking and current status of all resources (people, equipment, materials, customer needs, etc.).

MES system is a set of production information management system oriented to the workshop executive layer of manufacturing enterprises. MES can provide enterprises with manufacturing data management, planning scheduling management, production scheduling management, inventory management, quality management, human resource management, work center, equipment management, tooling management, procurement management, cost management, project Kanban management, production Management modules such as process control, bottom-level data integration analysis, and upper-level data integration and decomposition create a solid, reliable, comprehensive and feasible manufacturing collaborative management platform for enterprises.

Under the background of Industry 4.0, MES system is widely used in intelligent mattress automation factories. The system plays a great role in the manufacturing and production of mattress enterprises, helping enterprises to improve production efficiency, manage efficiency, quality problems, and effectively implement production plans. Julin Intelligent JL-MES system is equipped with a big data acquisition system, which can seamlessly connect with ERP, MES, three-dimensional library, dense library, WMS, WDS, WCS, and can customize mattress special conveyors and frame edges according to different needs of customers. Intelligent production equipment such as machine, edger, hoist, stacker, flip machine, lamination machine, glue spraying machine, packaging machine and special equipment for non-standard automation robots.

Features of Julin Intelligent MES System:

1. Use a powerful data acquisition engine and integrate data acquisition channels (RFID, barcode equipment, PLC, Sensor, IPC, PC, etc.) to cover the entire factory manufacturing site to ensure real-time, accurate and comprehensive collection of massive on-site data;

2. Build a factory The basic platform for data collection of the production management system has good scalability;

3. Using advanced RFID, bar code and mobile computing technology to create a closed-loop bar code system from raw material supply, production, and sales logistics;

4. Comprehensive and complete product tracking and traceability functions ;

5. Production WIP status monitoring;

6. Just-In-Time inventory management and Kanban management;

7. Real-time, comprehensive and accurate performance and quality analysis SPC;

8. Developed based on Microsoft .NET platform, supporting Oracle/SQL Server, etc. mainstream database. The system is a combination of C/S structure and B/S structure, which is easy to install and upgrade;

9. Personalized factory information portal (Portal), through the WEB browser, you can grasp the real-time information of the production site anytime, anywhere.

The problems solved by Julin Intelligent MES system:

Although ERP and field automation systems have developed to a very mature level, since the service object of the ERP system is the upper layer of enterprise management, it generally does not provide direct and detailed support for the management process of the workshop layer. For example, in the face of the following typical problems in workshop management, it is difficult for them to provide perfect solutions:

1. When there is a user product complaint, can you trace all the production process information of this batch of products according to the product text number? Can it be immediately identified: raw material suppliers, operating machines, operators, processes passed, production dates and key process parameters?

2. When the same production line needs to mix and assemble multiple types of products, can automatic verification and operation prompts prevent workers from assembling incorrect parts, product production process errors, product mixing and product handover errors? 3. What are the top 5 product defects on the production line in the past 12 hours? What is the number of defective products? 4. What is the quantity of each product in the warehouse and on the pre-process, middle-process, and post-process lines? Which suppliers do you want to supply to? When can I deliver in time? 5. How much time does the production line and processing equipment spend in production, and how much time does it stop and idle? The main reason that affects the production potential of equipment is: equipment failure? Scheduling error? Material supply is not timely? Insufficient worker training? Or is the process index unreasonable? 6. Is it possible to automatically conduct statistics and analysis on the quality inspection data of products, accurately distinguish random fluctuations and abnormal fluctuations of product quality, and eliminate hidden quality risks in the bud? 7. Can manual reports be abolished, and the production quantity, pass rate and defect code of each process can be automatically counted?

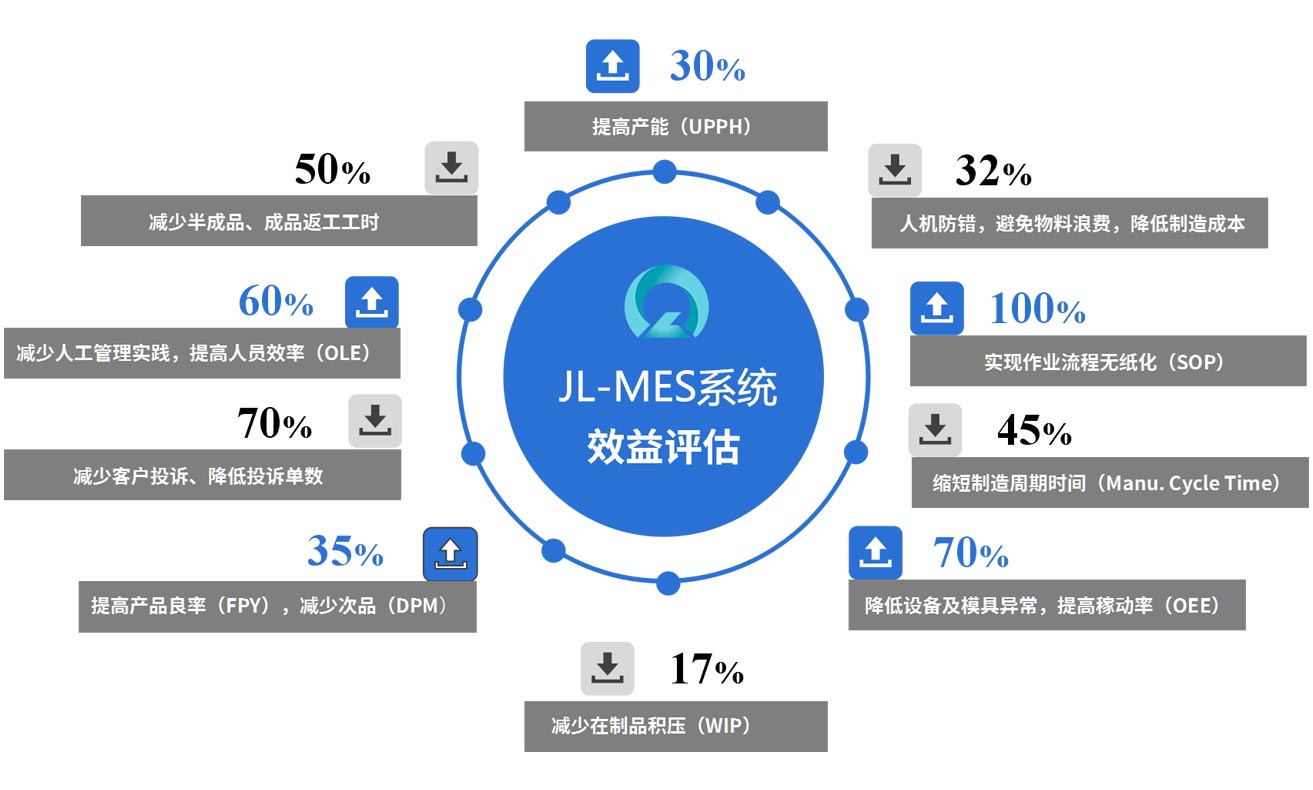

The value of Julin intelligent industrial MES system:

1. Realize the refined management of the production and manufacturing execution process;

2. Realize the seamless link between equipment automation and software automation;

3. Realize the powerful integration of enterprise resource information;

4. Realize logistics barcode and quality traceability management;

5. Realize the leap of enterprise information from islanding to integration; 6. Realize the efficient combination of pull-type production and push-type production.

Julin Intelligent |